A Rebate for Moving Dirt at Tussey Mountain Ski Area

An energy rebate for moving dirt. Sounds crazy right? It is not the typical light bulb or HVAC rebate usually offered by utility companies. It took some out-of-the-box thinking from the management team at Tussey Mountain Ski Area, but they did it. Tussey proved that by moving dirt, they would save energy and they received a check.

An energy rebate for moving dirt. Sounds crazy right? It is not the typical light bulb or HVAC rebate usually offered by utility companies. It took some out-of-the-box thinking from the management team at Tussey Mountain Ski Area, but they did it. Tussey proved that by moving dirt, they would save energy and they received a check.

The electric utility rebate helped fund the dirt moving project; however, the real value was garnered through reduced labor costs, reduced snowmaking costs, and the ability to open earlier in the season.

Here is their story…

Hire an Experienced, Independent Consultant

Tussey has been working with Ambipar Response EMS, Inc. based out of Bethlehem, PA to help guide their decision making. EMS works with ski resorts to provide assistance in energy efficiency, snowmaking systems engineering and environmental issues. EMS has developed methods to verify savings for snowmaking upgrades, qualifying for nearly $2,000,000 in rebates for its ski area clients. EMS has a broad range of experience with snowmaking efficiency and is not beholden to a specific technology so they can make unbiased, engineered solutions.

EMS had already collaborated with Tussey’s management and Board of Directors to develop a five-year plan to upgrade snowmaking at the ski area. The earth-moving project is one of the projects in this plan.

Opportunities for Energy Efficiency

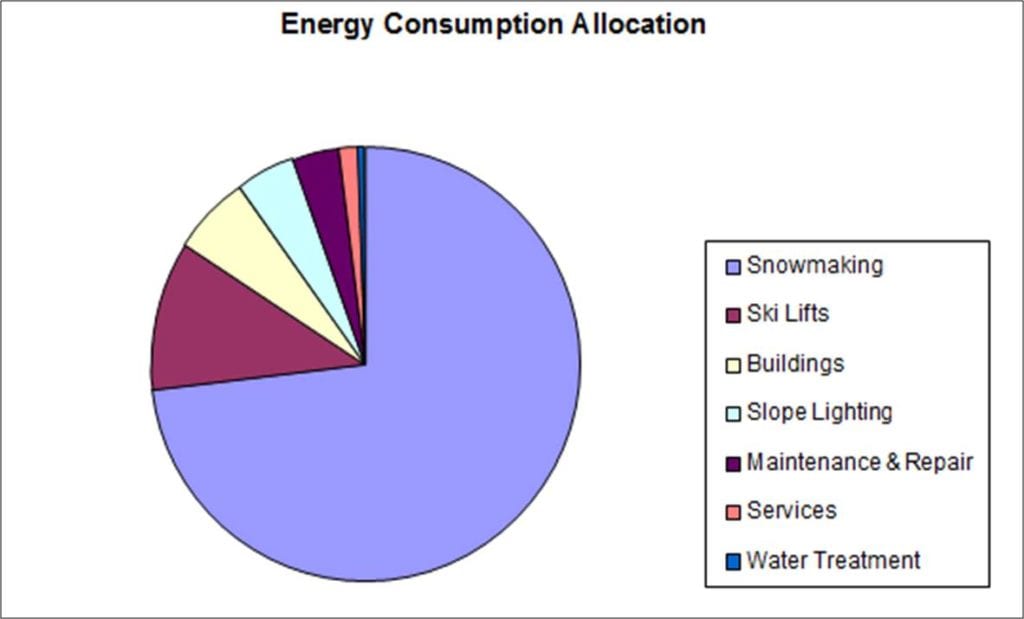

There were many opportunities for increasing energy efficiency at ski areas, but not a lot of capital to implement improvements all at once. Things like upgrading light bulbs to new LED fixtures make sense and are an easy fix. However, their impact on overall energy use at a ski area is small. Changes made to large energy users like snowmaking and ski lifts have a greater impact on overall cost to the resort.

It turns out that the low energy snow guns and snow fans are like CFL or LED light bulbs for the ski industry. Just like switching from an incandescent to a CFL or LED light bulb, switching to a low energy snow guns can save 75% or more of the energy cost to operate it. For the amount of energy used at ski areas for snowmaking, that is a lot of energy savings, translating into hundreds of thousands of dollars per year.

The problem is translating a highly weather-and site-dependent, industry-specific device into something the utilities can fit into their energy saving protocols. Building on work by Efficiency Vermont and collaborating with snowmaking manufacturers (DemacLenko, HKD Snowmakers, Ratnik, SMI, Snow Logic, Sufag/Areco, TechnoAlpin) and through a lot of analysis, measurement, and verification with the utilities, Ambipar Response EMS established a basis methodology for determining savings that it has been successfully using to get rebates for snow guns at various resorts.

EMS has further extended its ability to qualify for rebates for its ski area clients for other upgrades besides snow guns. These include water pumps and compressors. While upgrading water pumps and compressors does not normally save a sufficient percentage of energy to meet utility requirements, EMS has been able to evaluate and uncover sufficient project-based circumstances for specific cases that resulted in rebates, which leads to the moving dirt example.

Energy Rebate for Moving Dirt

Tussey Mountain prioritized improvements to increase efficiency and lower costs for its Tubing Park as part of its five-year plan. For the Tubing Park, EMS recommended several changes that would improve both the Tubing Park’s capacity and its operations. One recommendation was to re-grade the slope to remove the double fall line. By regrading, less snow is needed to groom level tubing lanes. Instead of making more snow and grooming out the slope (the multiple times needed to build and rebuild the park), Tussey could make just enough snow each time to support each lane without having to build it up with snow. Since this is a permanent reduction in snowmaking demand, Tussey would be reducing its snowmaking volume each season, resulting in a verifiable savings as established by EMS methodology.

Another recommendation for improving the tubing park was to improve the tow lift used to transport riders to the top of the tubing runs. It was determined that a carpet lift had more capacity than needed and capital costs too high to justify a move to that technology, in the near-term. However, the tow lift had significant operational issues with the potential for riders to disengage from the tow handles unless the snow track was laboriously maintained. Applying a permanently installed, low-friction plastic sliding track design used at a few other tubing hills provided a means to permanently set the track-to-tow-lift handle relationship to minimize the potential for disengagement. This track design also eliminated the need to make and maintain the snow track, significantly reducing labor and snowmaking requirements, resulting in both reduced labor and energy costs.

EMS defined the design parameters and coordinated the procurement and installation of the snow track and the slope re-grading for the tubing park. EMS also facilitated the purchase of a new grooming attachment that increased the capacity from 3-4 lanes to 4-6 lanes in the tubing park.

These improvements not only yielded a utility rebate to help pay for the tubing re-grading project, it has resulted in yearly savings in compressor and water pump energy and faster opening and recovery times for the Tubing Park. With faster opening and recovery times, Tussey Tubing is open more for business throughout the season.

If you’re interested in learning more about how Ambipar Response EMS can help your ski resort save as much money and energy as Tussey Mountain saved, please contact us here!