Snowmaking equipment at ski resorts: Snow guns vs. snow fans

Why do some ski resorts use snow guns while other resorts use snow fans? Why do some resorts use both? What is the difference? When skiers and snow boarders find out my company helps ski resorts increase energy efficiency and obtain rebates and tax incentives for their investments in energy efficient technologies, that is the first question they ask.

Why do some ski resorts use snow guns while other resorts use snow fans? Why do some resorts use both? What is the difference? When skiers and snow boarders find out my company helps ski resorts increase energy efficiency and obtain rebates and tax incentives for their investments in energy efficient technologies, that is the first question they ask.

In this article I will provide a brief overview of how snow is made and compare the two snow making technologies.

How to Make Snow

For most ski resorts, Mother Nature does not provide enough snow early in the season–or even during the season. So, ski resorts have to manufacture the snow themselves.

Snow is manufactured by combining forced water and pressurized air and spraying the mist into the air where cold temperatures turn the tiny water droplets into snow that falls on the slopes.

That is the simple description. In actuality, there is a lot more involved in snowmaking. There are infrastructure considerations such as:

- A centralized source of water

- A piping network and pumping system to deliver the water to the slopes at high pressure appropriate for the elevation of the snow gun

- A centralized network of compressors and a piping network to deliver compressed air to the slopes

- Electricity to run certain components

- Automation systems

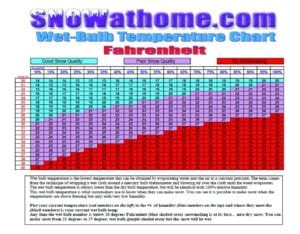

There are certain temperatures and humidity conditions where different snowmaking technologies have different performance ranges.

Lastly, there are different slope and wind conditions where different snowmaking technologies have different performance ranges.

Snow Guns

The feature nearly all snow guns have in common is that they utilize air that is obtained from a centralized compressor. The compressed air is piped throughout the mountain to the location of the individual snow guns. Separate pipelines are used to bring water to the location of the individual snow guns. The snow guns combine the air and water to create snow and spray it onto the slopes.

There are a wide variety of snow gun technologies. Snow guns fall into two main categories: internal-mix guns and external-mix guns.

Internal-Mix Snow Guns

Water and compressed air are mixed inside of a chamber before being forced through an atomizer. This process relies heavily on using large amounts of compressed air to ensure the mixture propels onto the trails.

Water and compressed air are mixed inside of a chamber before being forced through an atomizer. This process relies heavily on using large amounts of compressed air to ensure the mixture propels onto the trails.

External-Mix Snow Guns

Water and compressed are mixed outside of the snow gun rather than inside of a chamber. High water pressure sprays a fine stream of water through an adjustable nozzle while a stream of air blows through another nozzle. The stream of air intersects the water stream and breaks it into tiny droplets before spraying out of the gun and onto the trails.

Water and compressed are mixed outside of the snow gun rather than inside of a chamber. High water pressure sprays a fine stream of water through an adjustable nozzle while a stream of air blows through another nozzle. The stream of air intersects the water stream and breaks it into tiny droplets before spraying out of the gun and onto the trails.

There are a wide variety of automation technologies that can be applied to snow guns, including remote operation and adjustment of air/water mixtures depending upon weather conditions.

Snow Fans

The feature nearly all snow fans have in common is that they utilize air obtained from an on-board compressor and an external fan to propel the snow high into the air and onto the slopes. Snow fans do not require a centralized air compressor and associated air piping network. However, snow fans do require a source of electricity to operate the on-board compressor and fan. Water and air is mixed in a number of nozzles and propelled out of the fan to create snow. Automation features control air/water mixtures and the number of nozzles optimal for weather conditions. Many snow fans are mounted on towers with rotating heads so the snow fan can cover a wide area of terrain.

The feature nearly all snow fans have in common is that they utilize air obtained from an on-board compressor and an external fan to propel the snow high into the air and onto the slopes. Snow fans do not require a centralized air compressor and associated air piping network. However, snow fans do require a source of electricity to operate the on-board compressor and fan. Water and air is mixed in a number of nozzles and propelled out of the fan to create snow. Automation features control air/water mixtures and the number of nozzles optimal for weather conditions. Many snow fans are mounted on towers with rotating heads so the snow fan can cover a wide area of terrain.

Why Ski Resorts Use Different Snowmaking Equipment

Snowmaking is expensive. The equipment is expensive and the cost to operate the equipment is even higher. Various types of snow making equipment operate at different efficiencies, in different weather conditions, and produce snow at different rates.

Ski resorts must make efficient use of their limited capital by investing in upgrades related to existing infrastructure (air, electric, water pressure, etc). If a resort already has a network of piping in place for compressed air, it may not make sense to also invest in an electrical distribution system. Running electric service to remote areas can be very expensive! Conversely, if the resort does not have a centralized compressor network, it may be advantageous to run an electric service.

An individual snow gun may cost $5,000 to install while a snow fan may cost up to $50,000 to install. The value of snow fans is that they consistently make snow in the widest range of temperatures and can broadcast it over a wider area than a more efficient external-mix snow gun.

In general, snow fans use about 25% of the electricity necessary to operate traditional internal-mix snow guns. However, there are new, low-energy (external-mix) snow guns that are even more efficient than snow fans (they use less energy to make the same amount of snow).

Different makes and models of snow guns perform best under very specific conditions. Resorts spend a lot of time and effort determining which technology is optimal for each area of their mountains.

Incentives for Ski Resorts to Invest in New Snowmaking Technology

When resorts invest in more efficient snowmaking, operational costs go down. Payback on the investment is measured by the capital cost of the equipment vs. the operational savings over time. If savings are achieved in a short payback period, the investment makes good business sense.

There are additional incentives for resorts to invest in more energy efficient technology in the form of energy efficiency rebates and tax incentives. In many areas of the country, utility companies are mandated to offer incentives to companies that reduce their energy use. Snowmaking technology is not something the utility companies are used to evaluating so it often takes testing and performance demonstrations to prove they deserve the rebates, but that is what we do.

EMS helps ski resorts earn energy rebates and tax incentives by upgrading snowmaking equipment. Interested in learning more? Contact us here!

Allan is President of Ambipar Response EMS, Inc. EMS helps companies with environmental compliance and energy reduction strategies. Allan is also a member of the National Ski Patrol.