Modernizing snowmaking processes at Tussey Mountain

Like virtually all ski areas, Tussey Mountain Ski Area had a water problem. The snowmaking pumps and piping were not able to get enough water pressure at the top of the mountain to support the fan guns they had recently purchased. However, it was not just pressure—it was volume. There was not enough water for making snow on enough trails for a timely season opening. Further, the pumping arrangement was so difficult to operate that only one snowmaker could get all the pumps to operate together.

Like virtually all ski areas, Tussey Mountain Ski Area had a water problem. The snowmaking pumps and piping were not able to get enough water pressure at the top of the mountain to support the fan guns they had recently purchased. However, it was not just pressure—it was volume. There was not enough water for making snow on enough trails for a timely season opening. Further, the pumping arrangement was so difficult to operate that only one snowmaker could get all the pumps to operate together.

Increased Snowmaking Capability

Tussey Mountain management and its Board of Directors understood that in order to build its market share and be profitable, it must be more proficient and productive with snowmaking.

Tussey management talked to various types of vendors and ski areas but did not find a solution until their general manager met Barb Green, President of Blue Mountain Resort. Barb shared with Tussey the story of her successful experience with the professionals at Ambipar Response EMS—the ones who helped her get to the next level of snowmaking capability. She recommended Tussey contact EMS.

Snowmaking Assessment

EMS started with an assessment of Tussey Mountain’s snowmaking system’s barriers and opportunities. The assessment included the water pumps, compressors, water supply and storage ponds, water and air piping delivery systems, snow guns, system controls, trails, and operating procedures.

The pumping problem was critical, but a lot of what hindered snowmaking was setup time: trekking up trails, dragging hoses, hooking up snow guns, moving the guns, adjusting water flows, managing pumps, adjusting for changing weather conditions. Many snow guns were limited to low temperature operation only and the guns that could perform under most circumstances used so much compressed air that snow could only be made on one portion of one trail at a time.

Much of Tussey’s snowmaking pipes were close to the surface, resulting in the need to keep water flowing to prevent freezing. Occasionally, trapped water split pipe in a few areas, resulting in costly repairs and loss of snowmaking during critical weather windows. Pipe sizes had not kept up with the amount of snowmaking needed. Hydrants were not where they needed to be to support effective snowmaking without using very long hoses, which needed to be disconnected, properly drained after each snowmaking session, and removed to be out of the way of skiers.

EMS also worked with the management team to identify opportunities. The ski area had prepared terrain that could be skied if snowmaking could be made available without jeopardizing snowmaking on the critical opening trails. The varying skill levels of skiers and snowboarders could then be better accommodated. Tubing could be supported in a more timely way to be prepared for the holiday traffic. To learn more about the improvements made to Tussey Tubing by EMS, check out How Tussey Mountain Ski Area Got an Energy Rebate for Moving Dirt.

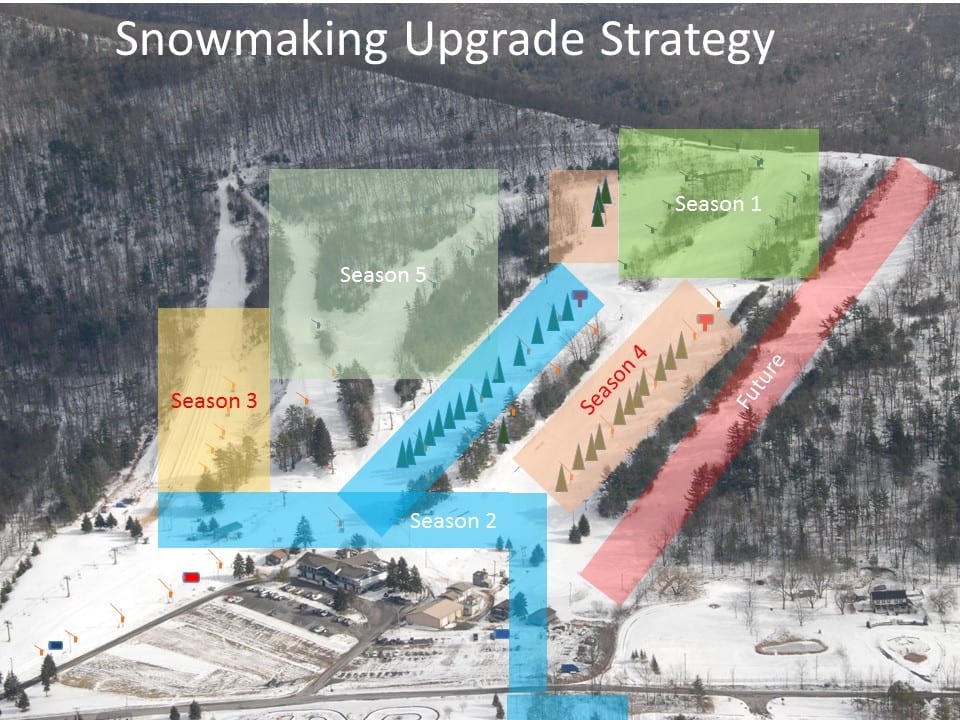

Snowmaking Assessment Results – A Five Year Plan

With all this input, EMS was able to develop a range of improvement options appropriate for the ski area’s needs, issues, and budget constraints. EMS presented its findings to the Board of Directors and management team along with specific recommendations for the most cost-effective improvements and their associated marketing and operational benefits.

The board wanted a plan that could be implemented over several seasons, with each season showing recognizable improvement to its guests. The goals were to establish a new level of snowmaking quality and snow coverage and faster opening and recovery. Together, the Tussey management team and EMS defined a five-winter-season plan to achieve the goals set by the board.

The plan addressed the board’s goals and management’s concerns along with the perpetual issue of limited labor. The plan leveraged the existing infrastructure to raise the level of performance for each new season. The board then asked EMS to assist the management team in implementing the plan.

Pumping Improvement Plan

The pumping improvement plan replaced two sets of parallel pumps (fed back to back) and a mid-mountain booster pump with one single, Variable Frequency Drive (VFD) controlled constant-pressure pump that increased water pumping capacity by 100%. Pump control went from sequencing startup of pumps and managing valves in multiple locations to a single start button and initially opening the main valve. From the previous hour or more startup, optimal, steady water pressure was available in five minutes. In addition, snow guns could be turned on and off as needed for coverage and relocation without having to adjust any valves, start, or stop pumps. The new pump also saved 25% of the energy used for water pumping for snowmaking. EMS helped Tussey get a $12,000 rebate from the utility for the energy savings.

Water Piping Delivery Plan

The water piping delivery plan gradually altered the piping system from a traditional loop to a star configuration, which prevented trapped water, allowed pipes to be incrementally replaced, and eliminated the need to manage a constant water flow. It also eliminated the wasteful need for always draining already pumped water back into the pond.

The first step in the piping delivery plan was to replace the main pipe from the pump house. EMS worked with Tussey to get a permit to cross under a state highway and helped them source cost-effective pipes. Legs of the water distribution system were upgraded to larger diameter pipes as new service areas were implemented. These new service pipes were sized for the new levels of service and augmented the support for existing trails. The result of the combination of the new pump and new pipes resulted in a 150-psi increase in pressure at the top of the mountain and sufficient flow to more than double snowmaking capacity.

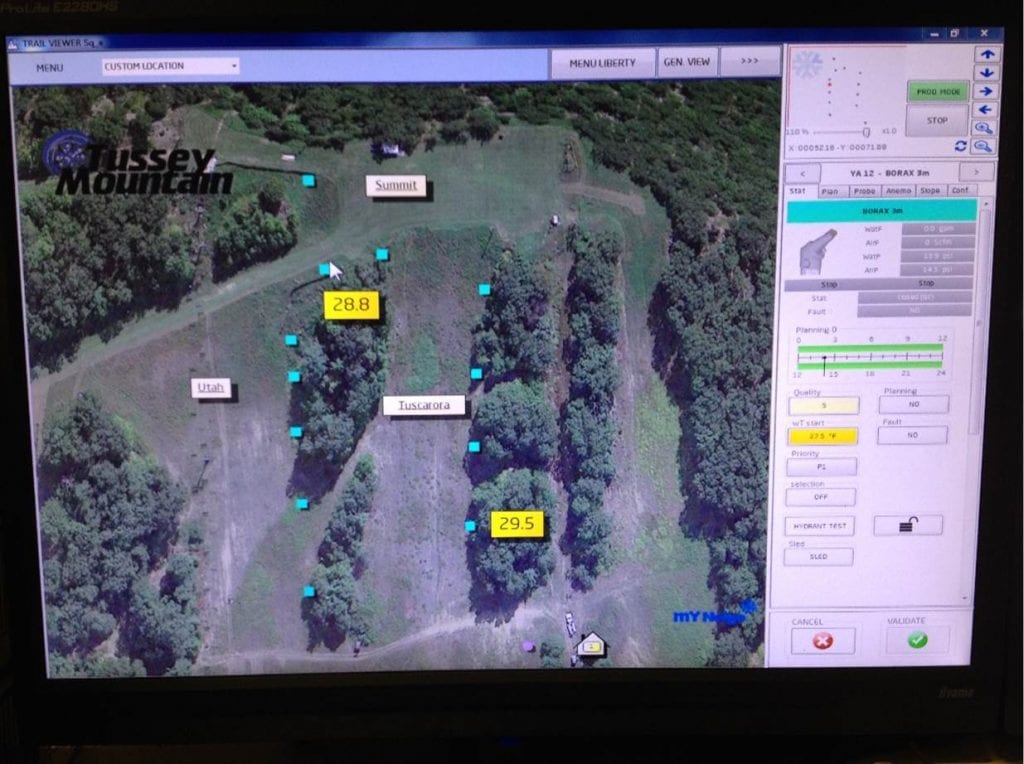

Snowmaking Automation Plan

The ideal solution for any ski area is fully automated snowmaking. The cost of this automation would have been prohibitive for a ski area the size of Tussey. However, a strategic mix of technology enabled Tussey to optimize performance, operating labor, and capital.

Automation was applied at the top of the mountain, where setup and adjustment on steep slopes takes the longest due to manual climbing rather than motorized travel. The internal-mix automated snow guns are also better suited to produce in the high wind conditions at the top and require less water pressure to operate, which avoided additional capital for higher pumping pressures. Automation at the top of the mountain, where snow is most visible from the highway, is also ideally suited for early season “marketing snow.” The automated guns produce snow without setup and automatically adjust to weather conditions, enabling better snow quality, which led to a first for Tussey—a Tussey employee received his first compliment and a tip from a guest as a reward for the snow quality.

Manual external-mix guns were placed lower on the mountain in more accessible places, where setup and adjustment is easiest and where the water pressure they need is the highest. The shift-selection control of the external-mix snow guns (rather than adjusting a continuous valve) reduced setup time when compared to that of manually controlled internal-mix manual snow guns.

The automation and simplified manual settings in snow gun controls reduced setup time at Tussey from hours to minutes.

Hydrant Placement Plan

Adding water and compressed air delivery piping enabled hydrant placement to optimize on-demand snowmaking. Without hoses to drag and snow guns to setup, snowmaking startup and shifting to new trails became quick and dynamic. This productivity improvement allowed more snow to be made in limited weather windows. The strategic placement of hydrants and snowmaking equipment also became an opportunity to create new trails within the existing ski area, which provided fresh terrain for regular guests.

Snow Gun Selection Plan

Most important to achieving Tussey’s goal of cost-effectively opening as many trails as possible, as early in the season as possible, was the selection of snow guns. Without the proper infrastructure of higher water pressure and additional hydrants, Tussey would not have been able to operate certain snowmaking technologies. Without these technologies, Tussey could not achieve its goal.

For the external-mix low-energy guns selected for the lower elevations, EMS worked with snow gun manufacturers to introduce new snow guns for the snowmakers to try each season. From among the external-mix guns, the snowmakers selected by consensus the snow guns most effective for them. This process enabled the operators to try new technology, choose the ones that worked best, and prevented them from returning to inefficient technology simply because it had worked for them before.

The first season the snow guns were used, there were only limited snowmaking opportunities before the Christmas holiday. However, Tussey was able to open sufficient terrain to have a profitable holiday opening. Without energy efficient, or “low-E”, snow guns, the snowmakers would not have had enough hours to make the opening goal.

Productivity Gains

To provide an example of the productivity gains, Tussey is now able to produce snow on two full trails simultaneously, where they could produce only on one portion of one trail before. Twenty-two low-E snow guns use the same compressor capacity as one of their workhorse internal mix snow guns. With the water to supply it, that is 22 times the productivity! Instead of buying more compressors, Tussey was able to get huge productivity gains with much less expensive snow guns and higher pressure water.

The key to solving Tussey’s snowmaking problems was solving the water problem. With higher pressure and more flow, more efficient snow guns could be used. With less or no setup, weather windows could be fully utilized. With more efficient snow guns, capacity could increase.

Tussey Mountain Ski Area is now opening faster and more fully. With the weather challenges of the last couple of years, where weather windows for making snow were brief, Tussey was able to have successful seasons. EMS helped Tussey imagine and create a better future for the ski area by considering all of their needs and helping them engineer a cost-effective path to get there. Contact Ambipar Response EMS if you would like to learn about how they can help your ski area!

For additional information, check out these articles:

How Much Does it Cost to Make Snow at a Ski Resort?

How Tussey Mountain Ski Area Got an Energy Rebate for Moving Dirt

Why Ski Resorts Use Different Snowmaking Equipment